Motorcycle Brake Rotor Grinding

Do this to ensure quiet shudder free brakesHere are the tools I used in this videoRockwell Jawhorse htt. The machine has a rotary electro magnetic table that turns under a rotating segmented grinding wheel.

How To Install Fully Floating Brake Rotor Buttons Youtube

Experience performance precision and profit with single setup two sides brake rotor grinding.

Motorcycle brake rotor grinding. It may be necessary to remove one or both front wheels for a visual inspection. Some stainless is not magnetic but the Honda rotor is. Then try spinning the wheel and mentally measure the resistance it gives.

Grinding is better any shop with a rotary grinder Blanchard could repair your rotor. There are several warning signs that mean a brake rotor has to get replaced. However unlike the car ones where the front and rear brakes are actuated by the same pedal bike rotors can be.

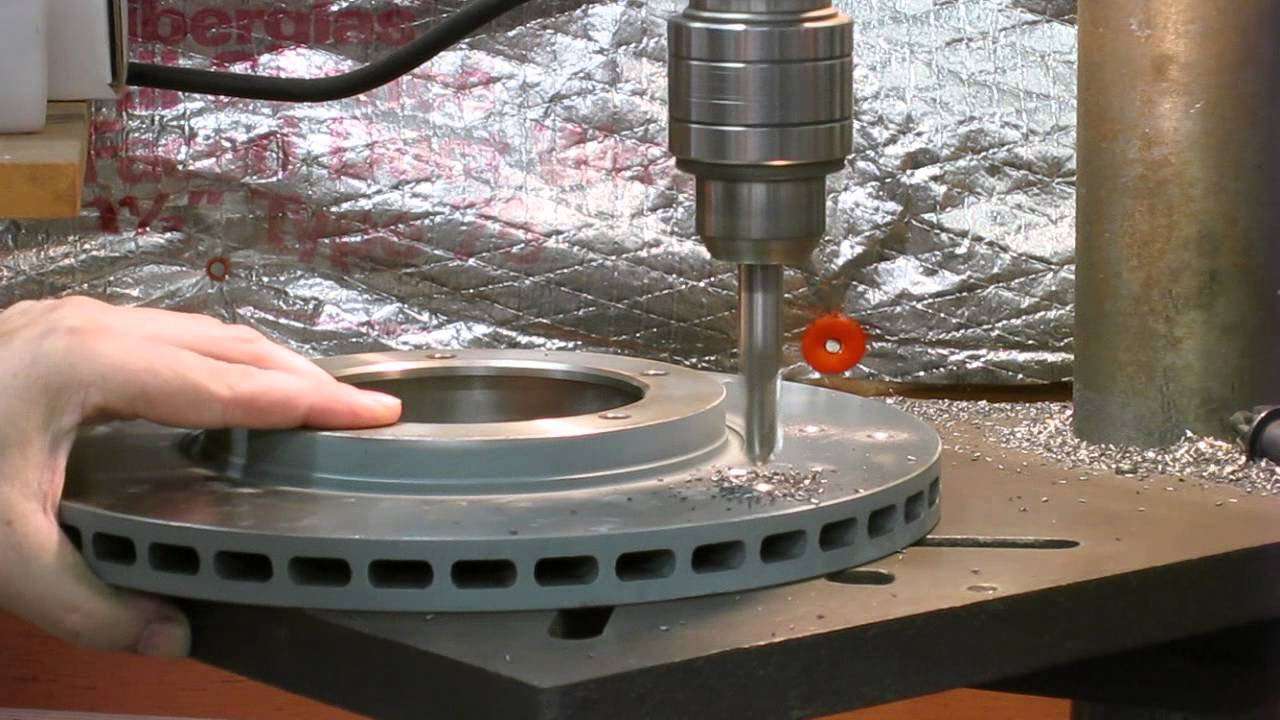

If you hear a grinding or growling sound then the brake pads are completely worn and are scratching the rotors. 84 028 37500 186gmail. All work is done in a mill and rotary index table using all cobalt tooling.

Bikers Choice Drilled Spoke Mount Front Brake Rotor For Harley Touring 2014-2021 108. If you look at a new brake rotor the radial swril grinding pattern came from a Blanchard type grinder. This listing is for drilling one motorcycle brake rotor with a 72 hole pattern.

A premier choice for vintage and performance rotor resurfacing where both appearance and performance count. 95 Bike Specific Exact Fit parts are designed specifically for your bike. They remove material very quickly.

This results in the brakes potentially failing putting the car and its occupants in danger. If you feel that you need to resurface a brake rotor companies like TrueDisk LLC are setup to do this quickly and cheaply. Sometimes your brake system might have debris from outside that stays in it and this debris could be little pieces of rock or gravel that gets stuck in the caliper.

Typically used for high hardness materials but with the proper grinding segments can grind most anything. Blanchard grinding technically rotary surface grinding is the only way to accurately and safely resurface a stainless steel motorcycle brake rotor. Simply ship your rotor to me and it will be returned within one business week.

70 Lin khu 5. Place a bottle or scissor jack under something strong on the rightside of the bike up at the front of the motor. At first I thought it was a bearing but as I went further along I am leaning more towards the sound being the break pads rubbing.

Being new to bikes I am wondering if it is common for the front break rotor to warp or if the caliper needs to be bled after break in. Come join the discussion about performance racing modifications classifieds troubleshooting maintenance and more. 00 169.

The mechanic will inspect your brake pads the rotors calipers and the brake lines feeding the calipers. Shop Advance Auto Parts wide selection of front brake pads rear brake pads front brake rotors rear brake rotors calipers drums lines boosters wear sensors and more. Best DIY brake rotor resurfacing before pad changes.

Resurface heavy duty truck brake rotors to OEM or better finish and accuracy in minutes. Starting hearing it on a ride this evening. It may also be necessary to test drive the vehicle if the source of the problem is not immediately apparent in order for the mechanic to verify the grinding noise.

And sometimes the debris will rest between the rotor and caliper which will cause scraping or grinding noises that will occur and possibly vibrates. Rather than using templates all patterns are designed using distance measurements and degrees so I can do any pattern you like at the same cost. Up to 8 cash back We highly recommend brake rotor replacement both front rotors and rear rotors in pairs to equally distribute stopping power.

A forum community dedicated to Honda Fireblade motorcycle owners and enthusiasts. Motorcycle brake rotors dont have much metal to spare for resurfacing but their brakes work better and more smoothly if new pads have a surface that has ha. The idea is to SAFELY get the front wheel off the ground to free spin.

This could result in a thinruined rotor. The part is held on the machine with a magnet. Motorcycle brake rotors work the same way as any car or truck brake rotors.

These custom rotors bring a heightened level of style to your wheels and they come in various colors to match the overall design of your bike. If the rotors get too hot they cant effectively do their job. Find conversations about your favorite CBR 900 or 1000 series RR models.

When youre due for a motorcycle brake rotor replacement you owe it to your bike to check out our massive selection of aftermarket brake rotors in amazingly innovative designs.

Motorcycle Brake Disc Grinding Machine Techduc Info Techduc Com Youtube

How To Dimple Brake Rotors Youtube

Flexible Honing For Motorcycle Brake Rotors Flex Hone Blog Brush Research Manufacturing S Company Blog

What You Should Know About Motorcycle Brake Pads

Motorcycle Brake Disc Straightening Maidstone Motoliner Ltd

Cut Rotors For Free Part 2 Youtube

How To Break In Motorcycle Brakes The Aftermarket Experience

How To Restore Motorcycle Brake Discs Youtube

Troubleshooting Common Brake Issues And Causes Haynes Manuals

Rotor Polishing On Stainless Steel Youtube

What You Should Know About Motorcycle Brake Pads

How To Eliminate Car Brake Grinding Noise Step By Step Diagnosis

Motomojo Motorcycle Brake Service

How To Clean Motorcycle Disc Brakes Caliper With Degreasing Cleaner

Brake Rotor Resurfacing Diy Auto Fanatic Youtube

The Flex Hone For Motorcycle Brake Rotors Flex Hone Blog Brush Research Manufacturing S Company Blog

Grind Go Kart Disc Brake Motor Braking System With Top Quality Oem Products And Hot Sell Motor Kart Disc Brake Buy Go Kart Disc Brake Grind Disc Brake For Motors Good Performance Motor Brake

Post a Comment for "Motorcycle Brake Rotor Grinding"